Customization

From idea to finished custom product

At FKI, we understand that standard solutions are not always enough. That’s why we offer a flexible customization service, where we quickly turn your ideas into finished prototypes. Our in-house development of both construction, electronics and software gives us full control over the entire process – from the initial sketches to the finished product.

This close integration means we can react quickly, optimize along the way and ensure that every detail meets your requirements. With short decision paths and in-house specialists, we can significantly reduce delivery times while maintaining high quality.

We have extensive experience in developing and producing small series of specialized products tailored to your specific needs. This can be anything from unique functional solutions and adaptations of existing models to completely new designs developed from scratch. Whatever the scope of the task, we always work with a combination of technical precision, functionality and durability – without compromising on design or usability.

Customer projects

Insertion Toaster

for a juice company

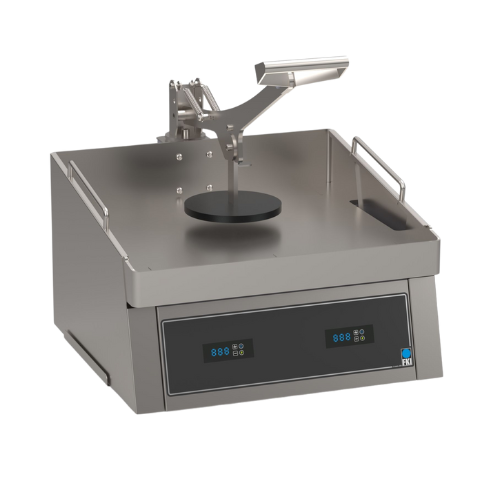

Smash Burger Press

to NOAH’s

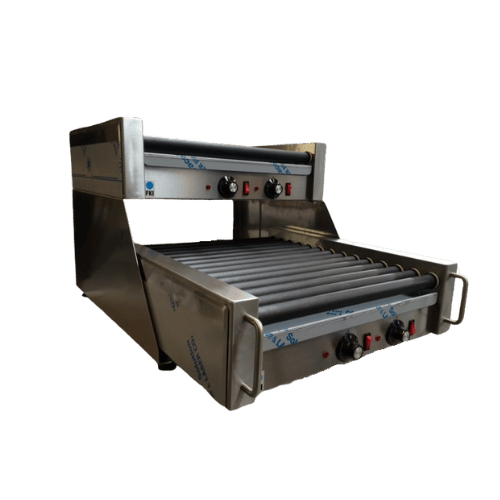

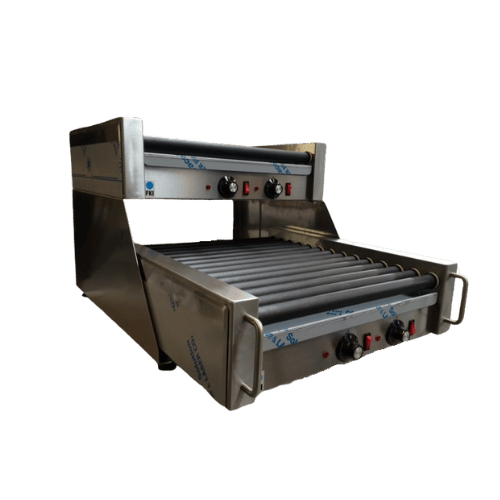

Advanced roller grill

to Orlen Poland

Roller Grill Atria 2.0

Atria/Sibylla Concept

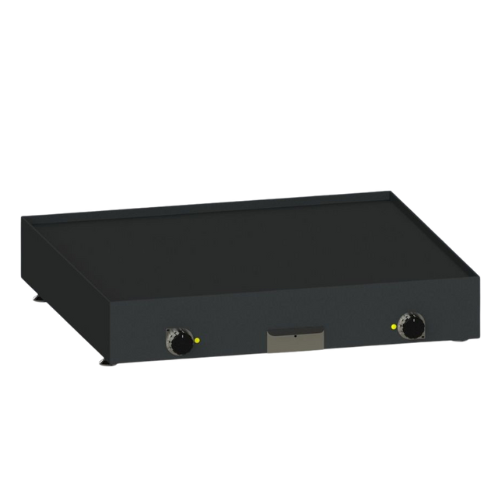

Vegan Sausage Grills and Roller Grills

Black equipment

to DDL and Circle K

Built In Sausage Grill and Roller Grill

to Biltema

Roller grills and Sausage grills

Grills in custom sizes

GLBT-UKV Conveyor Grill

for chain customers

Bridge with extraction

for limited space

Compact specialty toaster for new breakfast concept

A customer needed a toaster that could caramelize buns for a new breakfast concept. As space was limited, it was important that the machine took up as little space as possible. We therefore chose a solution where the customer’s existing toaster could be placed on top of the new machine.

The toaster had to be able to both caramelize and heat the buns as quickly as possible. From the time we received the brief to the first prototype, it took about three weeks. The machine can caramelize buns in just 30-40 seconds.

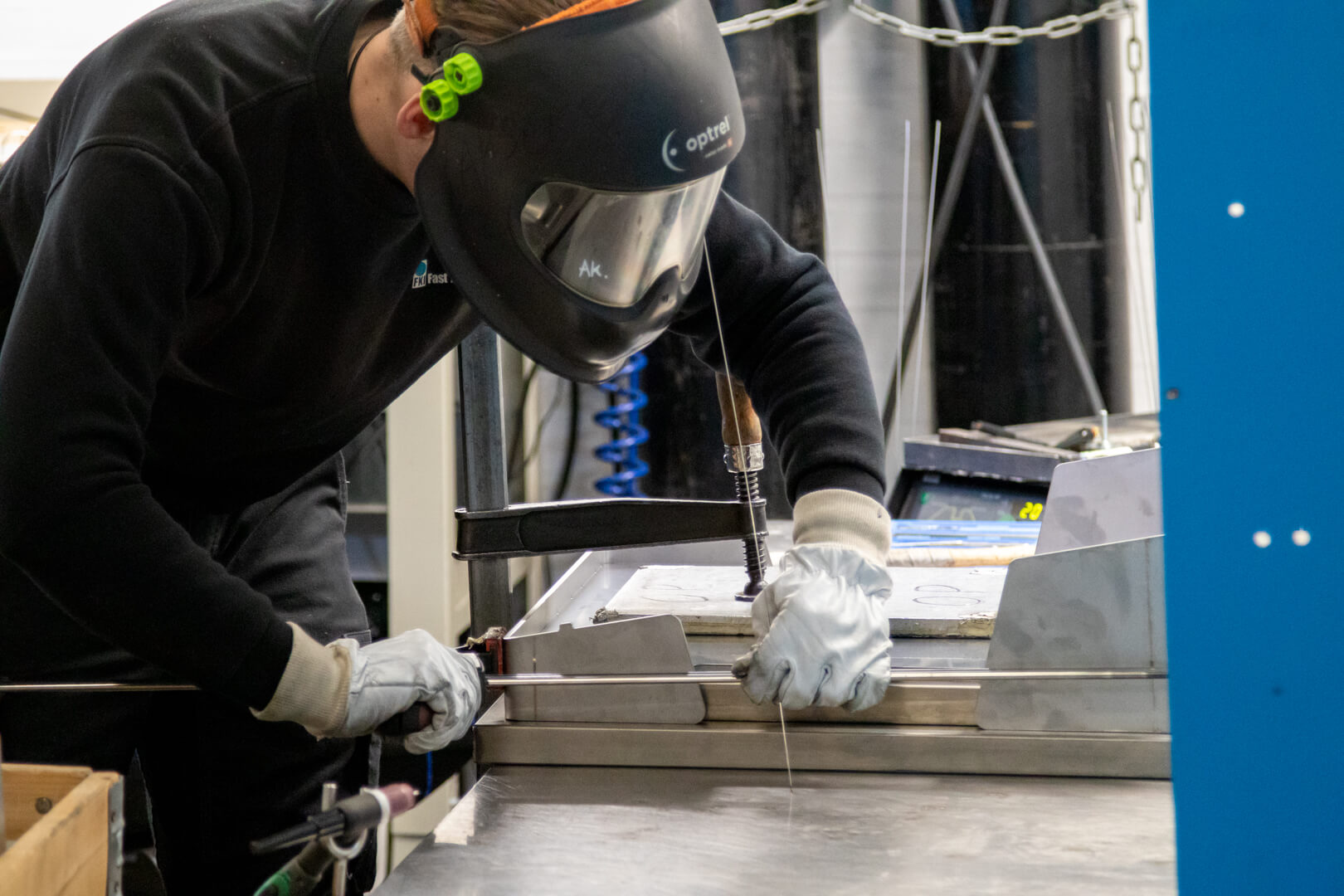

Integrated Smash arm for efficient Smash Burger production

NOAHs, a take-away concept, needed a solution that could relieve employees when preparing smash burgers. Normally, the burger is pressed manually with a handheld press, which is both time-consuming and physically demanding.

After a few visits to the kitchen, we came up with a design for an integrated “Smash arm” that can both press the burgers and rotate to utilize the entire pan. This results in faster and more efficient production. It took less than two months from the first meeting until the finished solution was in use in the kitchen.

Advanced roller grill for Orlen Poland

We were challenged by the Polish petrol chain Orlen to develop a roller grill with more precise heat control that would ensure that the sausages were always served hot and within the legal time allowed on the grill.

We started by developing a fully autonomous system that used AI to control the heating, detect when the sausages were ready for sale and monitor how long they had been on the grill. This way we could ensure optimal food safety while minimizing waste. We reached proof of concept, but the solution proved to be too costly.

However, the project resulted in an electronically controlled roller grill with improved heating properties and more precise control. In addition, we developed a timer that can be programmed to indicate when the sausages are too cold to sell, when they are ready, when it is the last chance to sell and when they should be discarded.

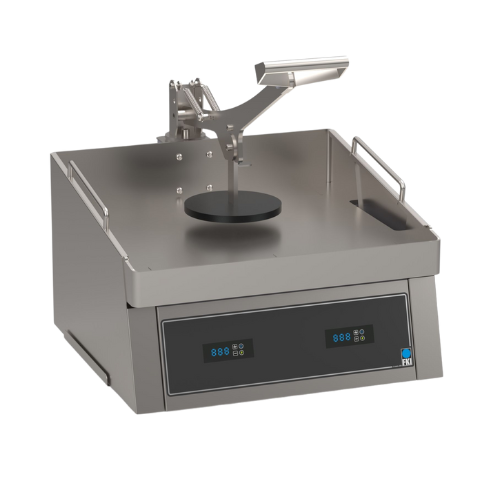

Roller Grill Atria 2.0

For our client Atria/Sibylla Concept, we worked with a design house to develop a roller grill that would tempt customers to order hot dogs by presenting the sausages more invitingly and visibly as soon as they entered the store.

The solution was to place the grill at an angle so that the sausages were closer to the customers’ field of vision. At the same time, red lights were installed under the sausages to simulate an authentic grilling experience. The grill could either be tilted for optimal presentation or flat for easier access when restocking the products.

Vegan Sausage and Roller grill – separated cooking

With the increasing demand for vegan products, we were asked by a customer to develop a solution that could separate conventional sausages from vegan sausages during cooking.

In the sausage grill, we solved the task by introducing a physical separation of the pan with a barrier that prevents contamination with animal fat. For our roller grills, we developed a similar barrier with a seal that ensures that fat from the conventional sausages cannot transfer to the vegan products.

It took about a month from receiving the assignment to being able to present a finished solution to the customer.

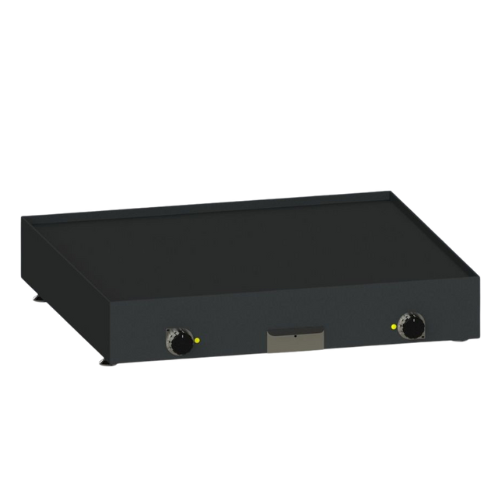

Black equipment for Deli de Luca and Circle K

When remodeling their gas stations, both Circle K and Esso Norge/Deli de Luca wanted a more exclusive look in their stores. They wanted to move away from the industrial look of stainless steel and instead have black equipment.

After researching the market for options to color our machines black, we tested several solutions. In the end, we decided to use the Teflon we already use on our pans and rollers. The Teflon is both heat-resistant and food-grade, which made it the ideal solution over paint or powder coating.

It took about a month from receiving the assignment to being able to present a finished solution to the customer.

Dismantled sausage grills for Biltema

In connection with the renovation of Biltema’s restaurants in Scandinavia, we have delivered a solution with built-in sausage grills. This provides both easier cleaning and a more elegant presentation of the products to customers.

As the grills are placed at the front of the counter, we have also supplied a remote control that can be mounted close to the staff for easy and efficient operation.

Roller grills and Sausage grills in custom sizes for Circle K

When remodeling their stores, Circle K replaced all counters with hot dog equipment. This meant that standard equipment was no longer suitable if the space was to be fully utilized.

In just two weeks, we produced three new roller grills and three new sausage grills, adapted to the new counter dimensions. The solution gave a nice, streamlined look and ensured that no space was wasted.

Over the years, we’ve delivered many customizations of equipment to optimize disk space utilization – both for customers who only need single special units and for those who need larger series.

GLBT-UKV Conveyor Grill

When several of our chain customers asked for a steak fryer that didn’t take up too much space but could also fry burgers without the need to install extraction, we came up with the idea for our GLBT-UKV Conveyor Grill as a solution for smaller gas stations and convenience stores that wanted to offer their customers burgers.

The machine cooks frozen burgers perfectly and evenly every time, and together with a toaster you have a small burger factory in very little space. The grill only takes up 450 x 750 mm and has a built-in extractor with carbon filter, so you don’t need to invest in an extractor.

Special bridge for double capacity in limited space

Many customers have limited space in their counters but want to increase capacity. For these customers, we have developed a special bridge where two sausage grills or roller grills can be placed on top of each other. The lower one can be pulled out for easy access to the sausages while retaining enough height for most standard counters.

Our distributors

We have a number of distributors in Denmark and Europe who sell our products. If you are interested in buying our products, you can find them by clicking on the button.